workingp rinciple

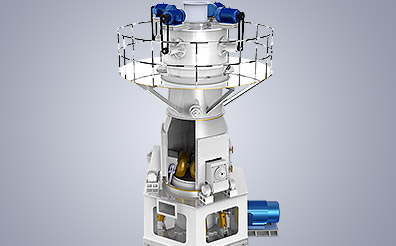

GSDF series micro powder grinding mill is composed of hammer crusher, elevator, storage hopper, vibrating feeder, mainframe, classifier, diffusion type double cyclone powder collector, pulse dust filter, high-pressure fan, soundproof room, muffler and etc.

There is 30-40mm gap between the pin shafts and the grinding rollers installed on the roller supports. When the roller supports revolve round the main shaft, the grinding rollers press the grinding ring due to centrifugal force. And at the same time, the grinding rollers revolve round the pin shafts due to the friction force. The raw material is quantified fed through the upper feeding tray and been throwing to all around. And the material will go through the gap between the ring and roller and be crushed and grinded by multi-layer rollers as powder under the effect of gravity. The grinded material falls down to the lower feeding tray and been blow up by the air going into the classification area. The qualified powder will enter into the final powder collecting system by classification rotor. The coarse powder will go back to the crushing and grinding chamber to re-processing again due to the centrifugal flow field action. The whole air conveying system is working under the full negative pressure condition without any powder overflow. It has the advantages of high efficiency, high classification accuracy, high reliability, nice work environment and less vibration.

technical parameter

| Model | GSDF32 | GSDF40 | GSDF50 | GSDF66 |

| Ring Diameter (mm) | φ800 | φ1000 | φ1250 | φ1680 |

| Roller Quantity (pcs) | 21 | 27/36 | 40/44 | 40/44 |

| Ring Quantity (pcs) | 3 | 3/4 | 4 | 4 |

| Main Shaft Speed (r/min) | 240 | 222 | 145 | 120 |

| Feeding Size (mm) | ≤10 | ≤10 | ≤10 | ≤10 |

| Output Size (mm) | 0.005-0.044 | 0.005-0.044 | 0.005-0.044 | 0.005-0.044 |

| Capacity (t/h) | 0.5-4.5 | 1-7 | 1.5-12 | 2-18 |

|

|

|

GSDF32 |

GSDF40 |

GSDF50 |

GSDF66 |

|

Grinding Mill |

Power(kW) |

75 |

132 |

185 |

315 |

|

Blower |

Power(kW) |

45 |

75 |

110 |

90*2 |

|

Classifier |

Power(kW) |

18.5 |

30 |

15*4 |

18.5*5 |

|

Hammer Crusher |

Model |

GPC400×600 |

GPC400×600 |

GPC600×800 |

GPC600×800 |

|

Power(kW) |

22 |

22 |

55 |

55 | |

|

Elevator |

Model |

GT210 |

GT210 |

GT210 |

GT250 |

|

|

Power(kW) |

3 |

3 |

5.5 |

5.5 |

|

Belt Conveyor |

Model |

300*60 |

300*60 |

400*80 |

400*80 |

|

|

Power(kW) |

2.2 |

2.2 |

3 |

3 |

|

Screw Conveyor |

Model |

GSC219*4.5 |

GSC219*6.9 |

GSC219*5 |

GSC273*8.6 |

|

|

Power(kW) |

3 |

4 |

3*2 |

5.5*2 |

|

Discharge Valve |

Model |

ZJD-200 |

ZJD-200 |

ZJD-250 |

|

|

|

Power(kW) |

0.75*2 |

0.75*1/1.1*2 |

1.1*2 |

1.1*2 / 1.5*2 |

|

Pulse Filter |

Model |

GDMC120 |

GDMC250 |

GDMC450 |

GDMC400*2 |

|

Air Compressor |

Model |

KSH150D |

KSH300D |

LG2.6/8 |

LG10/8 |

|

|

Power(kW) |

11 |

22 |

37 |

55 |

|

Overall Dimension |

( mm) |

13900x4000x6200 |

18000x4600x8600 |

14000x9000x10250 |

26300x7500x11900 |

Note: The production is based on open-circuit condition when bulk density of feeding is 1.6t/ m3. It is also relative to physics character,type of feeding, input size and composition etc. Sandmine machinery reserves all rights to change data without notice.